Nail Up Tiles

HOW TO FIT YOUR NAIL-UP TIN TILES

The Nail-Up tiles are a great product if you have a blank canvass for your ceiling, if you want to cover up an existing ceiling or level off an uneven ceiling.

But they are not just limited to being used on the ceiling. They make great wall coverings, decorative bar or counter fronts and have also been used outside with the proper protection in place. The possibilities are endless. Made the same way for over 130 years they have stood the test of time.

Each raw tin tile weighs 750g so they are lightweight, easy to cut using tin snips and bend around corners or curves.

How big are Nail-Up tiles?

The standard Nail-Up tile measures 600 x 600 mm plus the 10 mm overlapping nail flange

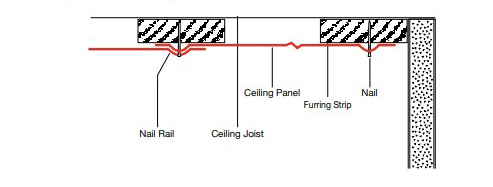

The Nail-Up tin ceiling tile has an overlapping nail rail that helps create a smooth transition from panel to panel and minimises the appearance of seams.

What to fix your tiles to

Our recommended method to install the tile is to fit a plywood substrate or furring strip grid spaced twenty-four inches on the centre. The grid must run in both directions to support nailing every six inches on all four sides of the panel.

How to install Nail-Up tiles

Map Your Lines

The first step of installing Nail-Up tin panels is to map out your positions. Run chalk lines from centre of the ceiling and work your way out toward the walls. Mark a centre point in the middle of the room. If you have a fixture installed, you can often centre the initial panel around this, or have 4 panels meet at the fixture. You can also start on the wall facing away from the door. That way, the panels are seamed towards the “dead” wall and won’t be seen from the entrance. This is recommended when using a white or light-coloured finish.

Install the Substrate

Nail-Up panels are installed using 1.5875, 18 gauge brad nails and an automatic nail gun. 25 lbs. of pressure on the gun will go through two overlapping tin Nail-Up panels. Brad nails are used around the edges every 150 mm. Although the tin panels are only 0.2 mm thick, they overlap and will show the seams.

Finishing

Without filler:

Cut the final rows of panels to fit flush against the walls. Trim out the edges with crown moulding or flat moulding.

With filler:

Install your panels up to your filler area. Cut the filler to fit flush against the wall. Nail the filler panel into the substrate, placing one nail every 152 mm around the perimeter of the filler panel. White colours need to have their edges caulked with white caulking; otherwise the edges will show.